An Unbiased View of Sheroz Earthworks

An Unbiased View of Sheroz Earthworks

Blog Article

All about Sheroz Earthworks

Table of ContentsSome Known Incorrect Statements About Sheroz Earthworks Some Known Incorrect Statements About Sheroz Earthworks Fascination About Sheroz EarthworksNot known Factual Statements About Sheroz Earthworks Some Ideas on Sheroz Earthworks You Should Know

For any earthwork professional, it is essential to carry out work with quality, accuracy, and on timetable. Using equipment control in job machines enables maximizing the various stages in the earthwork procedure, from preparing to the maintenance phase - trimble gps. The machine control system aids the maker driver in achieving the target aircraft promptly and quickly

The machine control system guides the operator with centimeter precision. With Xsite PRO 3D, you'll constantly understand exactly how much to reduce or load. Your regional Xsite technical support can direct you and help with any kind of troubles without seeing the website. Remote support conserves time and money, as it lessens downtime in jobsites.

The smart Trick of Sheroz Earthworks That Nobody is Talking About

Our system's parts are very carefully designed to endure the rough problems of construction websites. Comparison of the exact same project carried out using device control versus the typical technique exposes that, on standard, the traditional method calls for 50% even more time to achieve the very same task as the technology-assisted technique.

Get in the Xsite equipment control system; it's right here to give you with a significant benefit when functioning with earthmoving equipment. Discover just how Xsite Equipment Control can boost your efficiency and make certain work security! Xsite Maker Control systems can be mounted to any excavator from mini excavators to big mining excavators.

How does equipment control work? In 2D systems, the equipment is furnished with adjusted inclination sensors. These sensing units are placed on the pre-determined parts of the maker in excavators the sensing unit are usually mounted to the frame, boom (or booms), miner arm and to the quick coupler - trimble parts. By utilizing the data obtained from these sensors the system can compute the specific setting of the excavators bucket idea in relevance to a recommendation point.

The system is extremely simple to discover the fundamentals can be shown in under one hour of training. With Xsite you don't need to bother with learning all the tips and method simultaneously. Extra training and directions are constantly readily available over remote support when required. Contact your regional Xsite supplier to discover more! How does the remote assistance job? A cordless internet connection makes it possible to establish a remote link in between the maker control system and the solution center.

The Facts About Sheroz Earthworks Uncovered

Xsite Equipment Control systems support open common data formats, making it possible for smooth info flow from one system to an additional. Depending on your option of system (with or without placing, i.e., 2D or 3D), your device is outfitted with inclination sensing units, a controller unit, and a display/operating panel.

Many software and hardware remedies exist to help identify a device's current setting on the earth and contrast it with a desired design surfaceand construction drivers can do even more to utilize the benefits. Maker control is making use of different placing sensing units and a display screen to provide the driver with a recommendation in between the position of the pail or blade and the target grade.

Depending on the arrangement, equipment control systems can offer the operator with a simple visual guide to container or blade setting, or can automatically relocate the blade to grade by speaking to the device's hydraulics - https://www.reddit.com/user/sherozau/. There are equipment control systems available for practically any kind of device: , dozers, excavators, soil and asphalt compactors, scrapes, trimmers, crushing makers, and pavers

Sheroz Earthworks Can Be Fun For Everyone

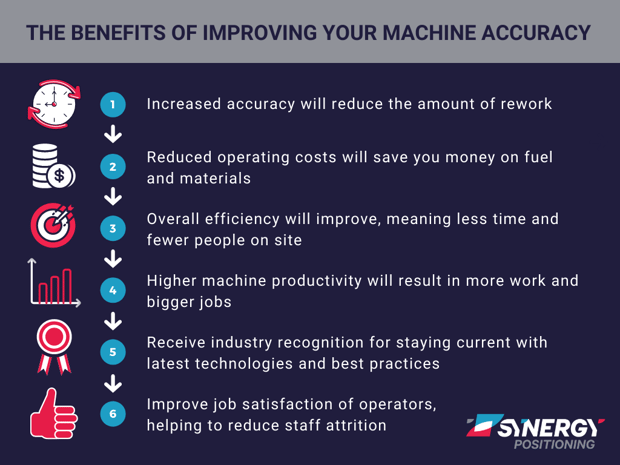

Maker control can also assist raise efficiency and reduce overall costs. Construction devices without maker control will certainly become a point of the past and the advantages got from it will be many.

Trimble equipment control systems give a myriad of benefits to any person who uses earthwork equipment and, at EarthCalc, we can provide you with 3D files for your machine control-enable devices. Uncertain if machine control is worth the expense? Consider the complying with reasons that you need to consider this choice.

Making use of general practitioner aligned with your 3D layout files, these systems essentially ensure that you will certainly eliminate or put the correct quantity of product at the building website. On many construction sites, This Site revamp is an usual and discouraging fact, but with Trimble device control, you can get rid of the requirement for rework.

The Of Sheroz Earthworks

Typically, with Trimble machine control, you can get rid of excess devices at a specific job site. For circumstances, a work that might have required making use of three or four pieces of digging deep into tools currently might need only two tools to achieve the very same task in less time. This allows you to relocate your tools to an additional task website and deal with numerous work at one time.

Report this page